Alex O'Sullivan

Mechanical engineering student with experience in aerospace, motorsport, and robotics. Passionate about all forms of manufacturing from blacksmithing to 3D printing.

With too many projects and a penchant for leadership, I spend my time either building my next project, or helping those around me realise theirs.

// Projects & Experience

EirSpace Student Rocketry - DoE

Lead a multi-disciplinary team of 50+ engineering students from across Ireland in designing, simulating, and successfully launching two Mach 1.0+ high power rockets.

Initiated and maintained a safety-led composites workshop, teaching layup best practices and protoyping critical airframe components such as nosecones, body tubes, and other control surfaces

Represented EirSpace at industry events such as PyCon, effectively marketing EirSpace as Ireland's first inter-collegiate student rocketry organisation

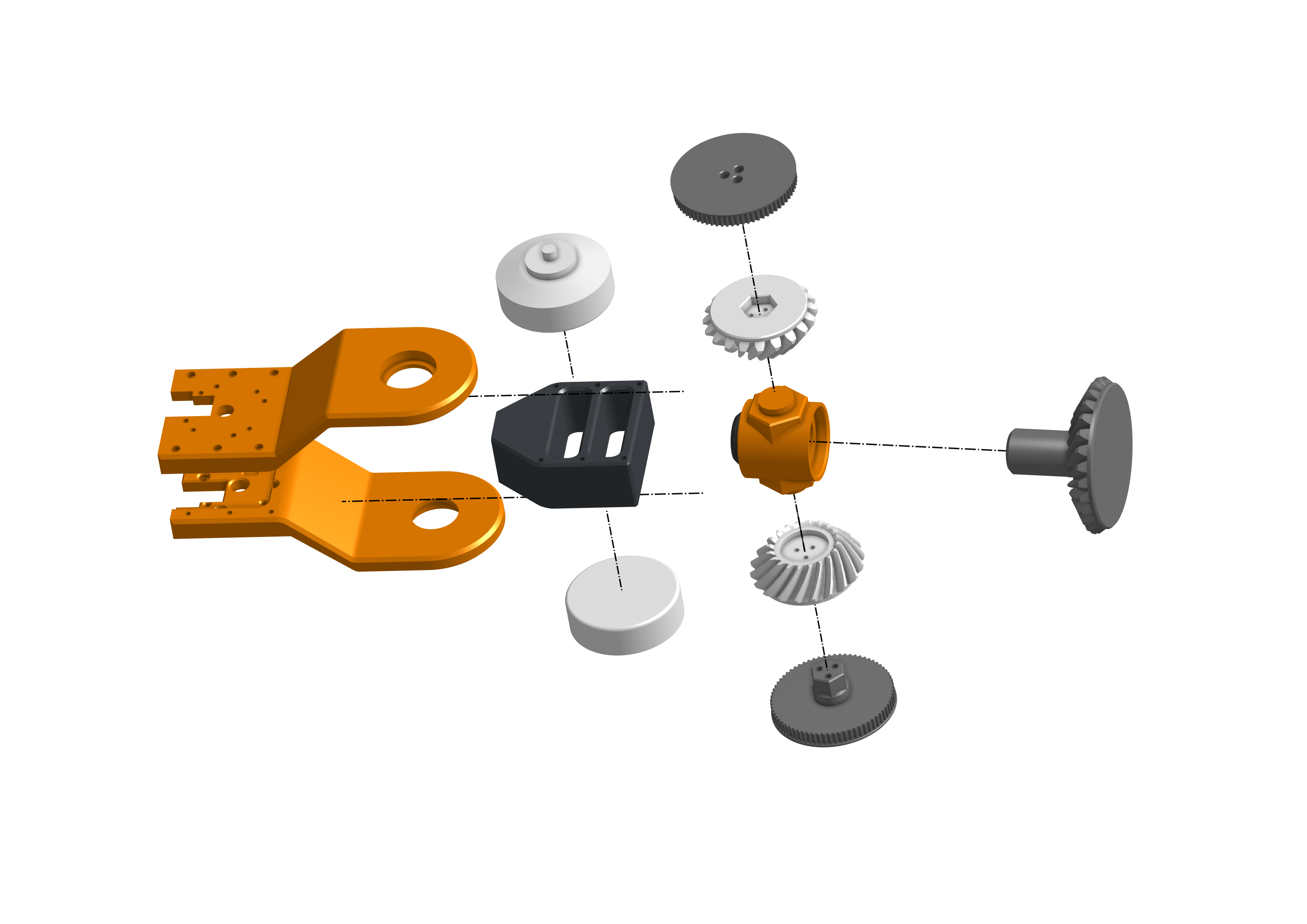

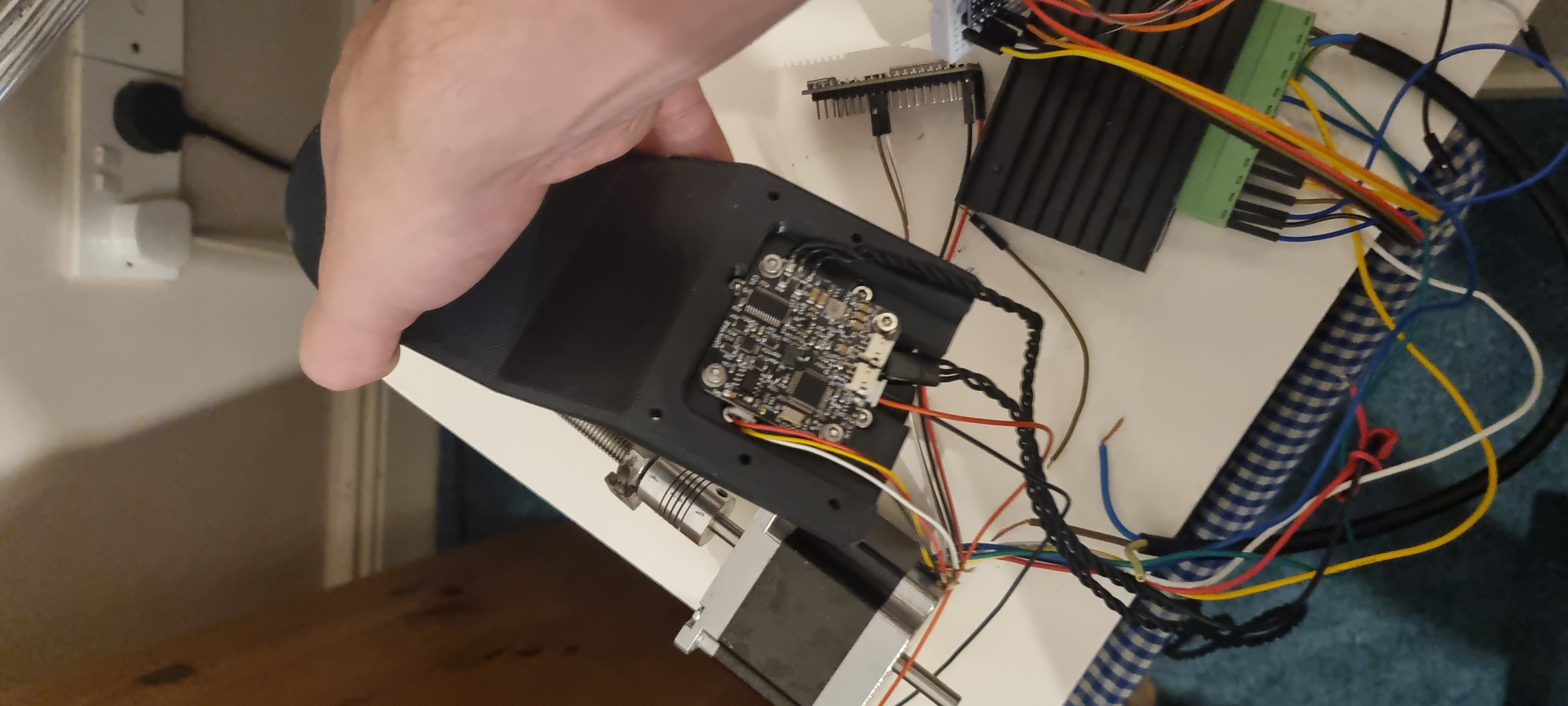

Closed-Loop Robotic Differential Wrist

Designed a belt-driven, differential helical bevel gear system for controlling a 2 DOF wrist in OnShape. Development of elbow joint is WIP.

Integrated sensor-driven motor controllers, with high-speed communication to enable responsive and precise feedback loops via CANbus.

Learned Python to communicate with BLDC driver boards via open-source serial-to-CANbus libraries (As a mechanical engineer, this was the hardest part!!).

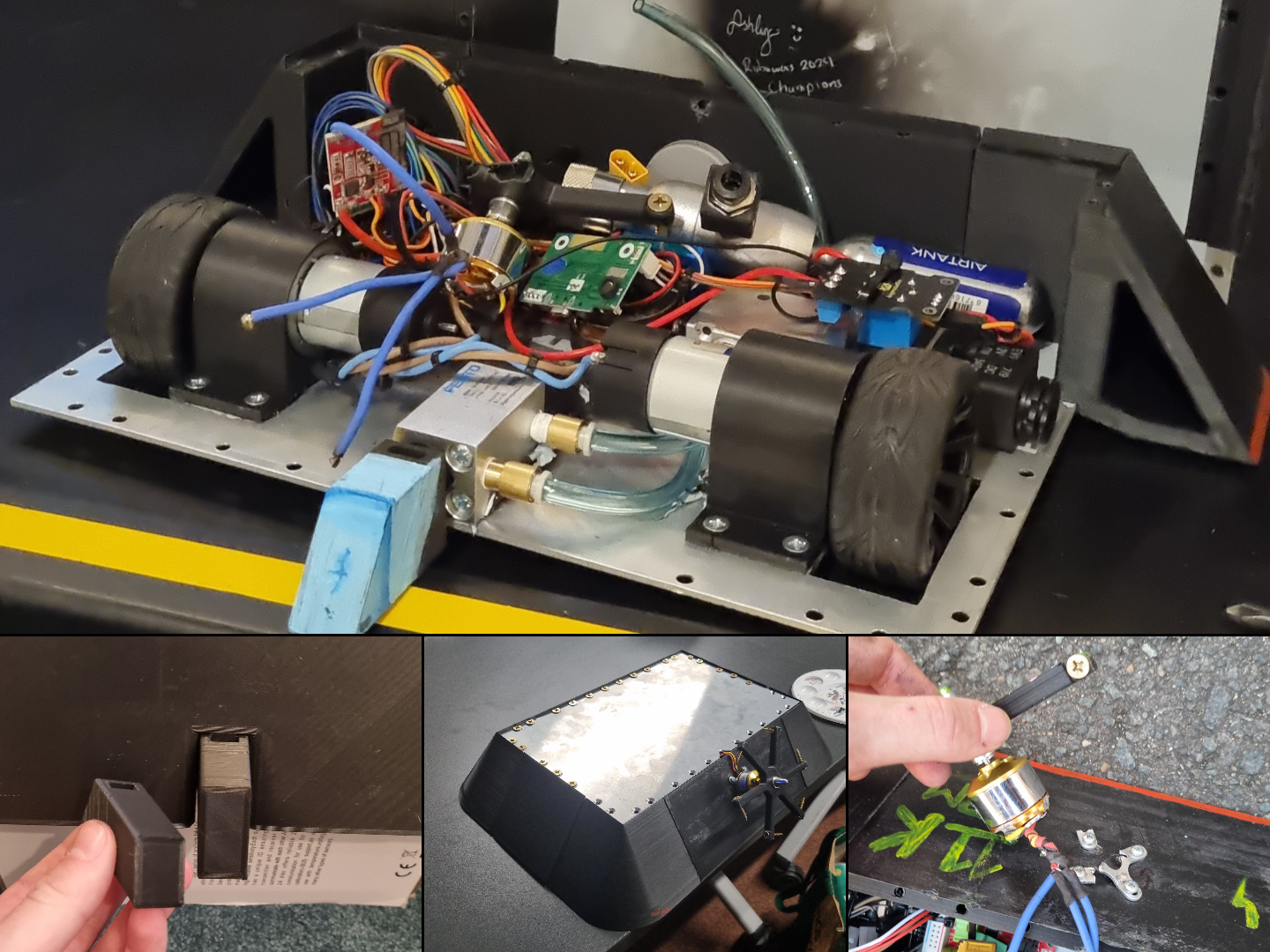

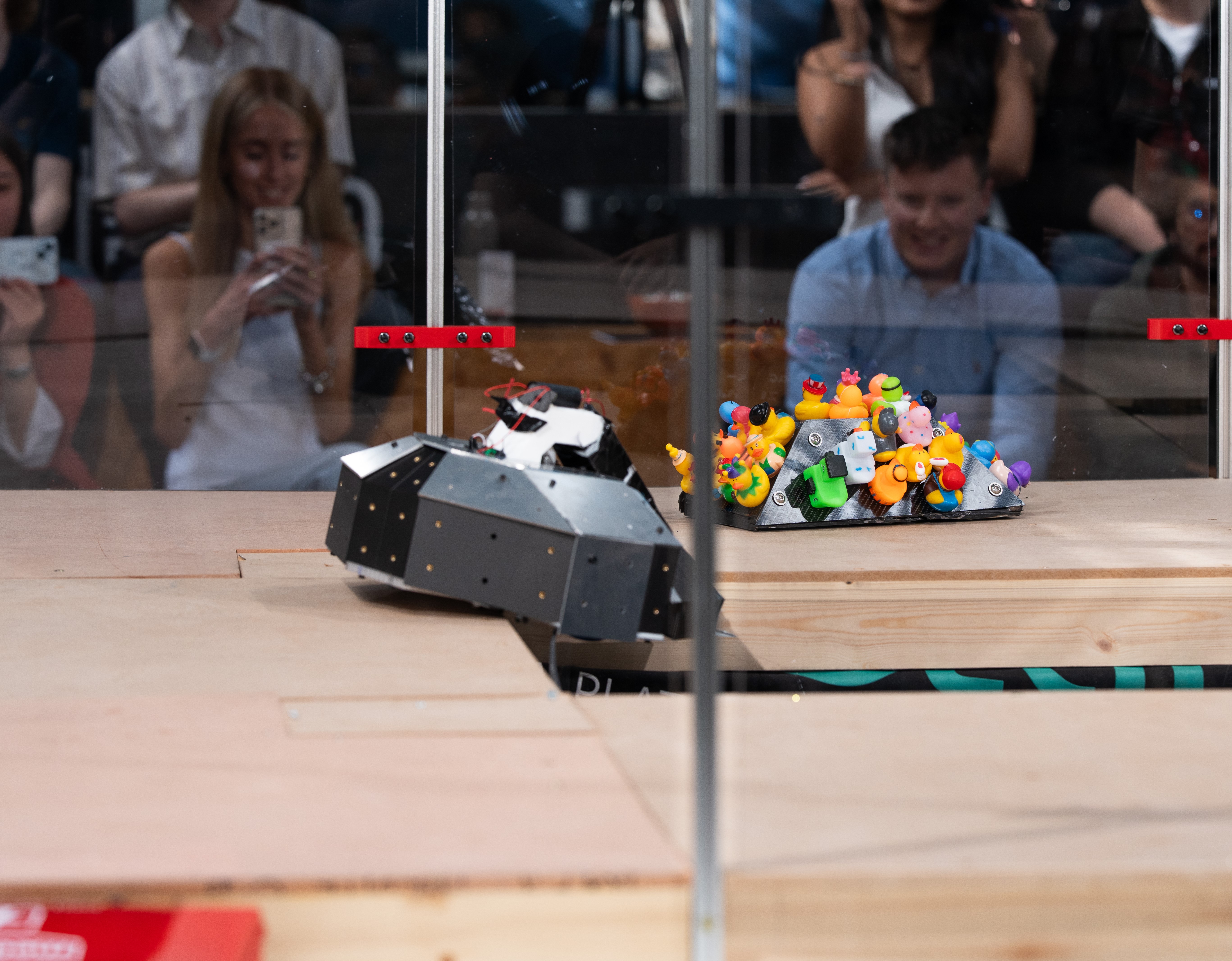

RoboWars - Champion & Lead Organiser

Designed and built a remote control fighting robot with a pneumatic piston system and high-speed spinner weapon, winning the RoboWars competition in 2024.

Joined the organising committee the following year and scaled the competition from 3 to 6 teams, and from 25 to 200+ audience members in attendance. Teams upskilled in electronic and mechanical building techniques, with a pneumatic flipper design taking home the gold

Collaborated with some of the most prominent Irish hardware startups, such as from Bobby Healy - CEO of Manna Drones, Cian Donovan - CTO of Akara Robotics, and Lucy Daly - Progamme Manager of Patch. The event was a huge success and I'm currently working on RW 2026!

Formula Trinity - Drivetrain Engineer

Designed, simulated, and built drivetrain components for Formula Trinity, a student-led motorsport team. Worked on components such as the rear sprocket, wheel hubs, and uprights.

Traveled with the team to the famous Silverstone racing circuit in England, where our team was amongst the lowest budget in the competition of over 50 university teams from across the world.

Despite the low budget, Formula Trinity has won numerous awards and trophies, such as 1st in Cost & Manufacturing, 2nd in Autonomous Racing Design, 2nd in Concept Class, and Most cones collected in a single lap (Autonomously!).

// Other Achievements & Projects

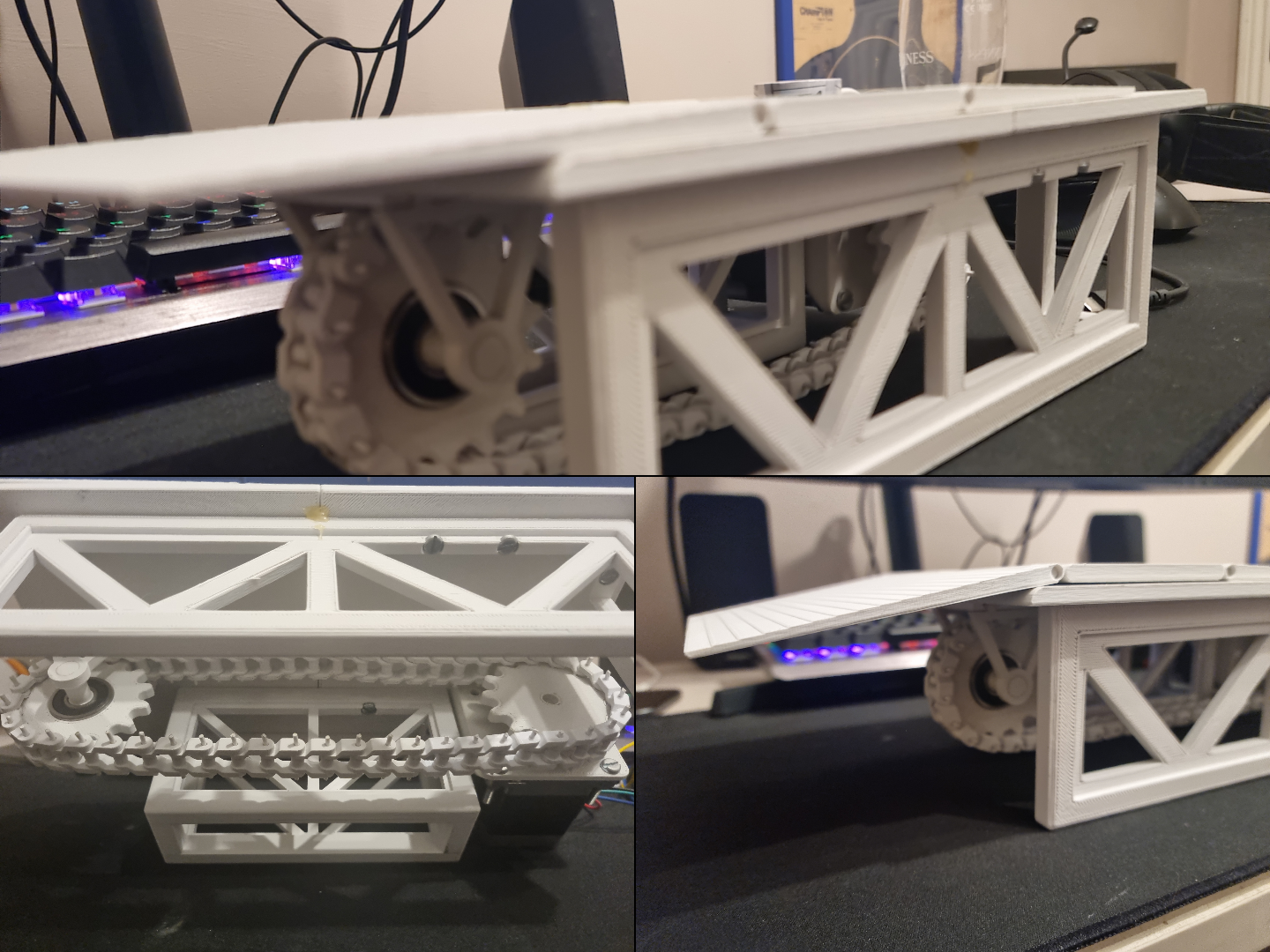

// Identified a valuable problem of improperly parked vehicles costing car park owners upwards of 300,000= a year. Worked with a team of two software engineers to choose the necessary sensors and actuators to detect, lift, and move illegally parked cars in high-density car parks. Modeled and fabricated a scale version of our design to work with Little Tykes cars, demoing our final version to investors at Patch Demo Day 2023

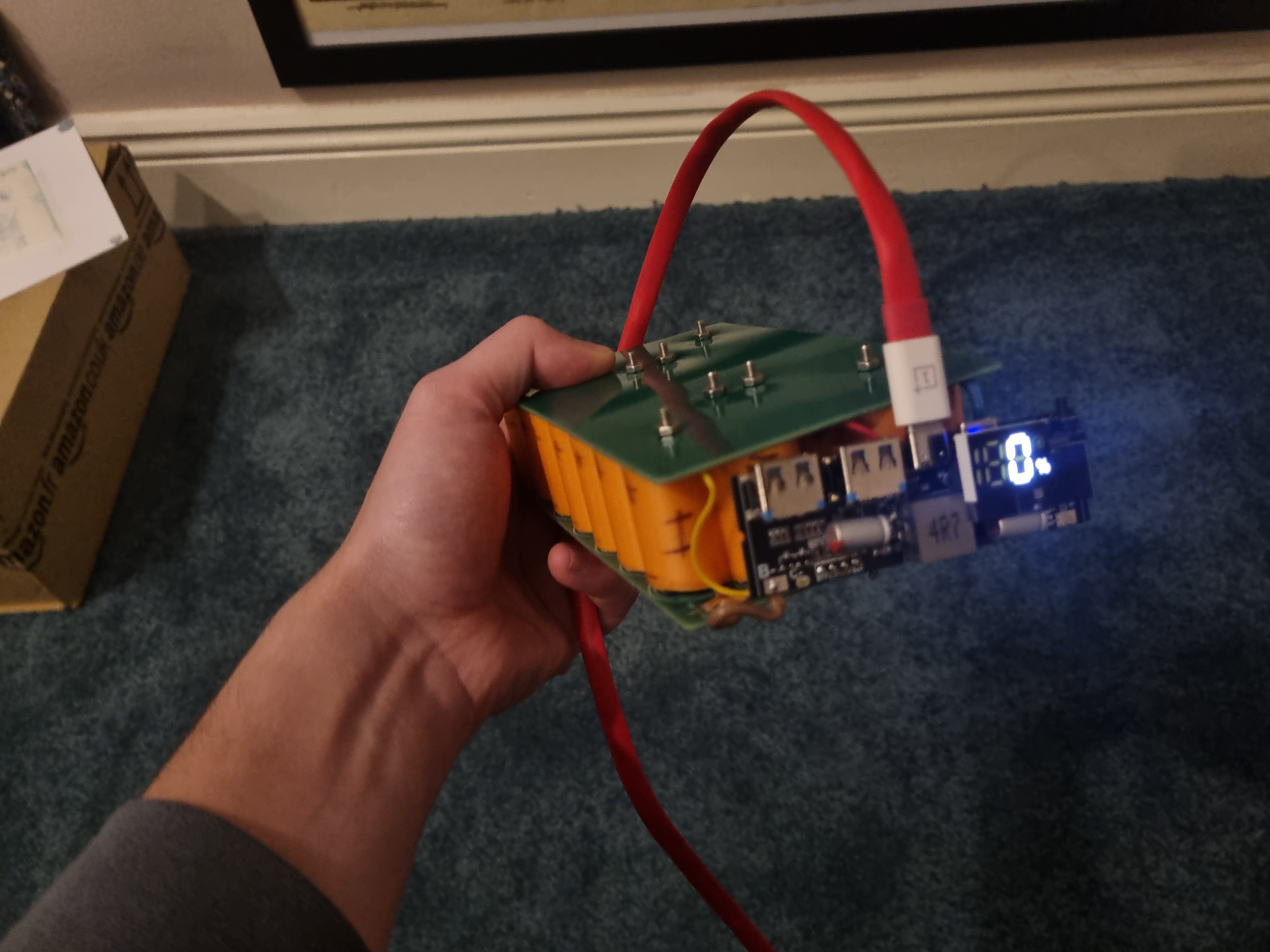

// Using 35 batteries extracted from discarded disposable vapes in my area, I designed two custom PCBs and assembled a 100W fast-charging powerbank for less than 30 euros. Using a commercially available battery management board, I was able to charge both my phone and my laptop to 100% in roughly half and hour, demonstrating the incredibly wasteful nature of our disposable attitudes as a society.

// Melted down scrap alumnium parts to create recycled ingots, for use in future casting projects. Forged tongs, punches, and other blacksmithing tools in a propane-fueled gas forge. Welded custom skateboard bracket for a folding bike, as well as other tools for metalwork projects. Worked on agricultural sprayer rebuilds as well as custom motorcylcles, including rebuilding my Dad's old carburetor (twice).

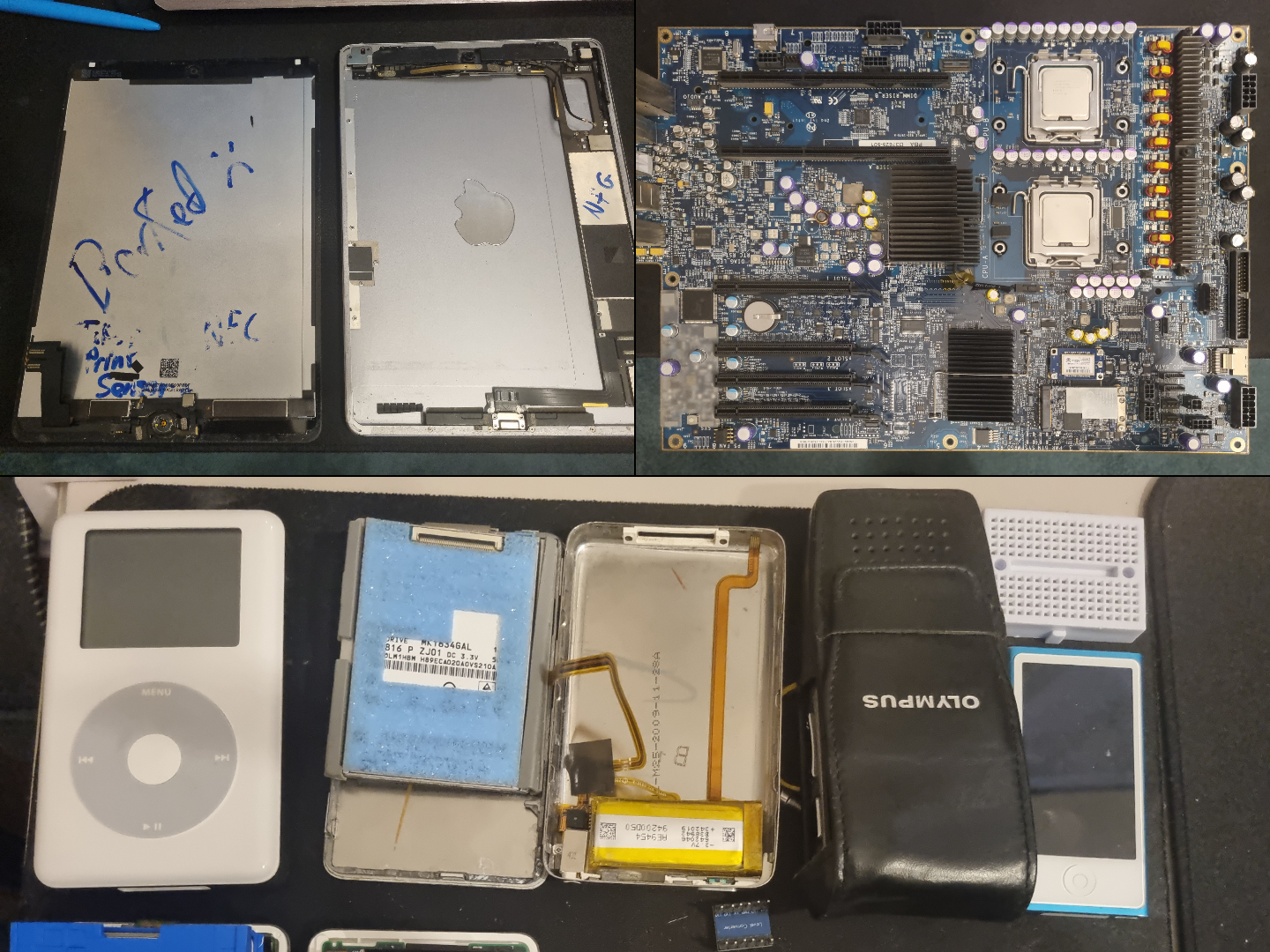

// Specced and built my first PC at the age of 14, and have since upgraded and modified it, moving from Windows 10 to Ubuntu (and soon to Arch!), falling deeper into various FOSS (free open source software) rabbit holes and projects. Currently working on a new PC build to fit into an old Mac Pro case from 2008 that I found in a bin.

// I needed a nice DSLR camera for RoboWars photos and for livestreaming the event. Because the budget didn't allow for us to buy our own camera, I got an old broken one from my brother for free. I diagnosed the issue as a broken SD card slot, which was visibly mangled from the inside and did not read SD cards anymore. I bought the replacement SD card daughterboard, swapped it with the old broken one within the camera, and re-assembled the camera. The replacement worked and we had a working DSLR for RoboWars.

// Designed and implemented a number of features for a distributed WiFi testing solution. A network of Raspberry Pi Pico MCUs connect to and test a target WiFi network, allowing schools, businesses, and building owners to gain realtime insight as to the health and performance of their mesh WiFi network.

// Used Fusion360 to model a sliding ramp mechanism to be retrofitted into existing DART rail carriages, allowing wheelchair users to access public transport without manual ramp setters. Used this design to create a 3D-printed scale model using a stepper motor and Arduino microcontroller. The stepper motor would advance a preset number of steps in either direction to 'deploy' and 'retract' the model's access ramp.

// Alongside an EE friend, we specced and built a quadcopter that used two on-board Arduino MCUs, one for ArduPilot control software and one for radio communication. Another Arduino was built into a custom remote controller, the frame of which was designed in Fusion 360 and printed on our Ender 3 FDM 3D printer. Yes I put a drone-shaped hole in my parents' ceiling.

// Replaced batteries on a range of devices, such as 5x iPad Air 2, 4x iPod Classic 3rd - 6th Gen, Samsung Galaxy S9, Macbook Pro 2008, Macbook Air 2015, and many more. Also repaired tape-playing mechanisms such as worn belts on a Sony M450 Microcasette Dictaphone.